Remember to use the correct level of filter efficiency to ensure harmful fumes and fine particulate dust are not being spread around the workspace. Welding with stainless steel produces chromium. Make sure you know what you are welding before you start. The hazards will depend on the type of welding, the materials (base metals, surface coatings, electrodes) to be welded, and the environmental conditions (outside or in a confined space).” Advice:Īsk for a material safety data sheet (MSDS) to identify the hazardous materials used in welding products and the fumes that may be generated. “Before beginning a welding job, it is important to identify the hazards for the particular welding operation. “A welder should also be aware of the risks of welding stainless steel,” warns the American specialist Vicki Bell in several publications. Personal protection equipment is tantamount to improving the working conditions of welders and protecting their health.

#Hexavalent chromium stainless steel portable#

Risk assessments can be conducted with a specialist in ventilation and filtration systems to determine if a business requires an engineered solution or if using a plug-and-play mobile or portable extractor is the right choice for the workplace’s daily operations.

#Hexavalent chromium stainless steel professional#

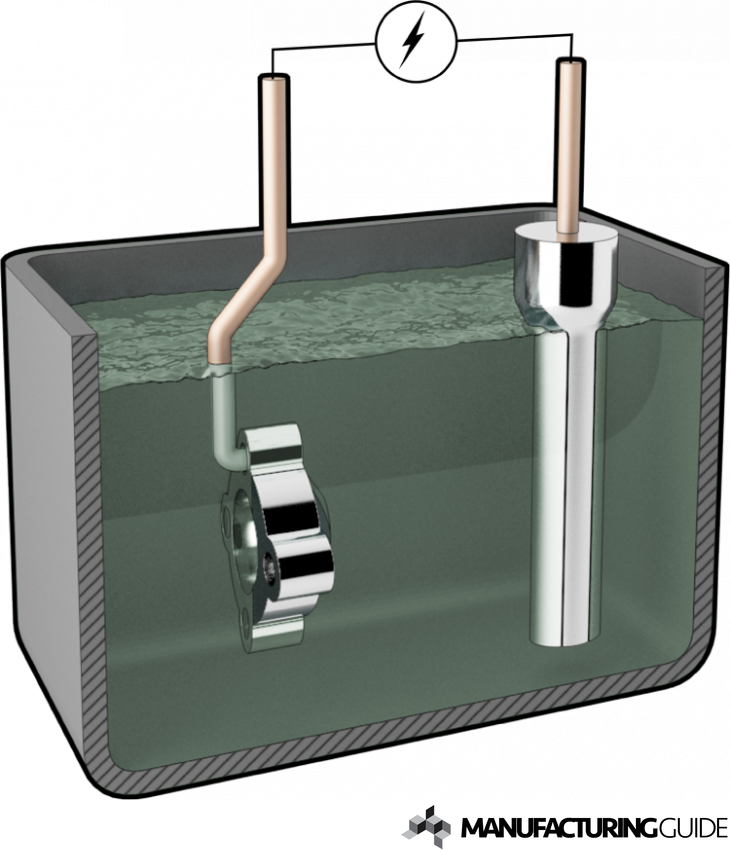

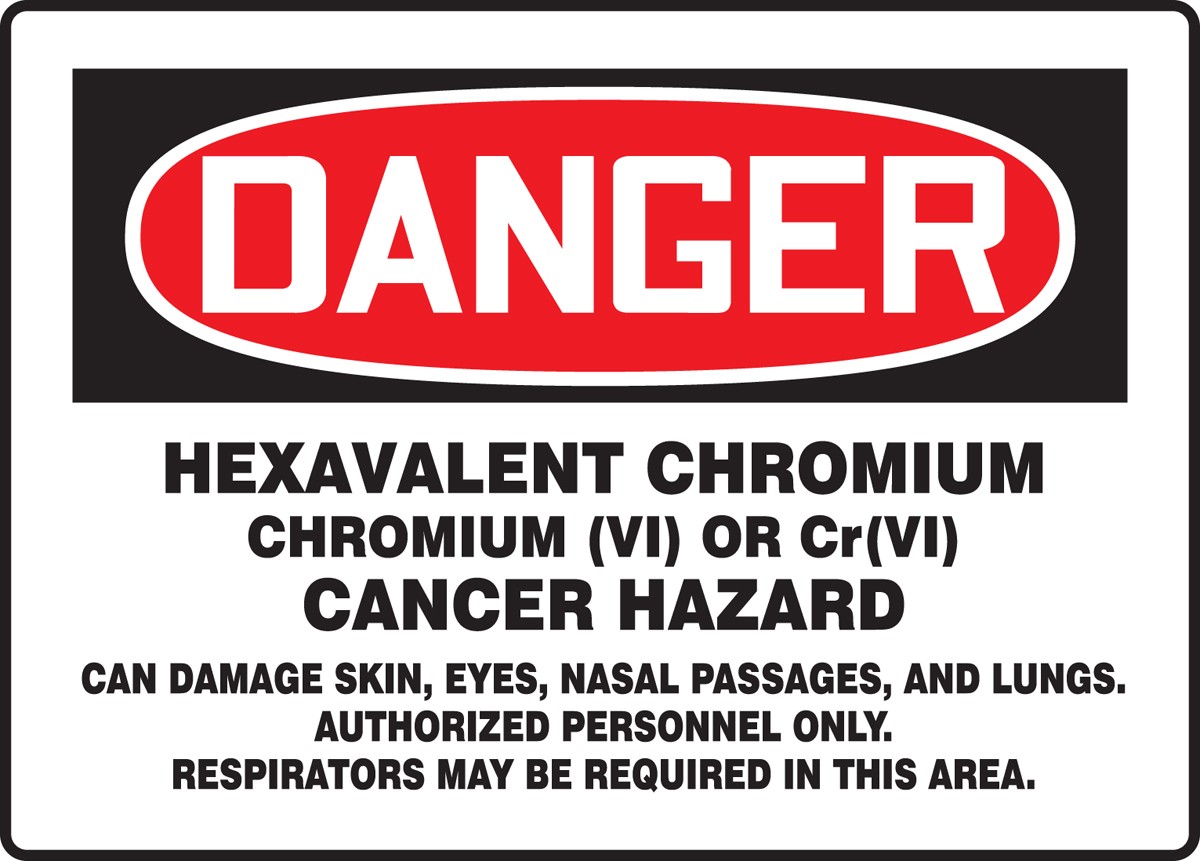

Preventative measures to protect welders against fumes from welding stainless steel with proper and professional ventilation systems and the correct fume extraction equipment are important to protect long-term health. Improve the working conditions of welders and protect their health. MMA welding and FCA tend to produce the most fumes. MIG and MAG generally produce quite a lot more fume. TIG produces the least fume although it does produce significant amounts of ozone and nitrous oxide both of which are irritant gases. The most common methods are:Ībout 80% of welding operations use this method:Īnd 5% of specialist companies use this for specific applications: The amounts of fumes released during the welding of stainless steel depend largely on the welding method used. Cr(VI) fume is highly toxic and can damage the eyes, skin, nose, throat, and lungs, and is a known carcinogenic. The production of these elements occurring in welding with stainless steel and the welding fumes created are proven to have serious effects on the health of welders and people in the welding environment. During the welding process, chromium is converted to its hexavalent state, Cr(VI). The majority of those steel grades contain nickel. Chromium is the basic alloy element of all groups of stainless steel. For example, exposure would likely be considerably higher in a confined space than it would be in a new building under construction or a pre-fabrication shop.Welding stainless steel is a common process, which raised concerns for the work environment. The work environment makes a big difference too.Point of operation ventilation systems are the best in terms of exposure reduction. Adequate ventilation makes a big difference with regard to exposure.The higher the concentration of chromium, the higher the potential for overexposure to hexavalent chromium once it’s heated. Some types of steel have more chromium than others.For example, TIG welding produces a fraction of the fumes that stick welding or arc gouging produces. Some hot work methods produce fewer fumes than others. The concentration of chromium in the steel The amount of exposure depends on the following factors: The primary exposure to mechanical construction workers occurs when hot work is performed on stainless steel. This is a heavy metal substance that can cause lung cancer and other health problems over time, if inhaled in significant concentrations.

One of the health hazards workers may encounter during “Hot Work” is hexavalent chromium. Many of these can be controlled with proper work practices and personal protective equipment (PPE). Safety hazards from these operations include burns, eye damage, electrical shock, cuts, and crushed toes and fingers. Health hazards from welding, cutting, and brazing operations include exposures to metal fumes and to ultraviolet (UV) radiation.

Welding, cutting, and brazing are addressed in specific standards for the general industry, shipyard employment, marine terminals, and construction industry. The risk from fatal injuries alone is more than four deaths per thousand workers over a working lifetime. Welding, cutting, and brazing (Hot Work) are hazardous activities that pose a unique combination of both safety and health risks to more than 500,000 workers in a wide variety of industries.

0 kommentar(er)

0 kommentar(er)